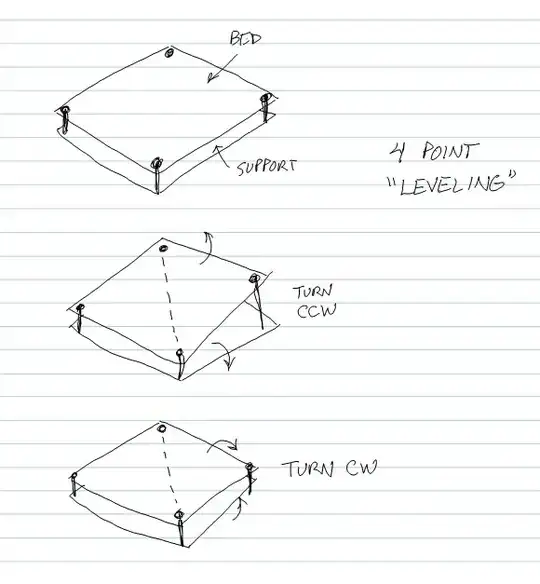

My Ender 3, and I think lots of printers, have 4 bed leveling adjusstments, one at each corner. It seems to me that having 4 points produces an over-determined system, making it confusing to get the leveling right - adjusting one of the four may have little or no effect, but then cause a later adjustment elsewhere to have effects that violate a least-surprise principle.

Would it be better to have only three points? Or is the fourth necessary/useful with non-completely-rigid bed structures to add rigidity?