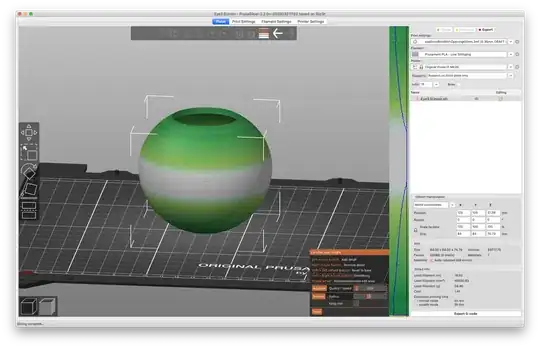

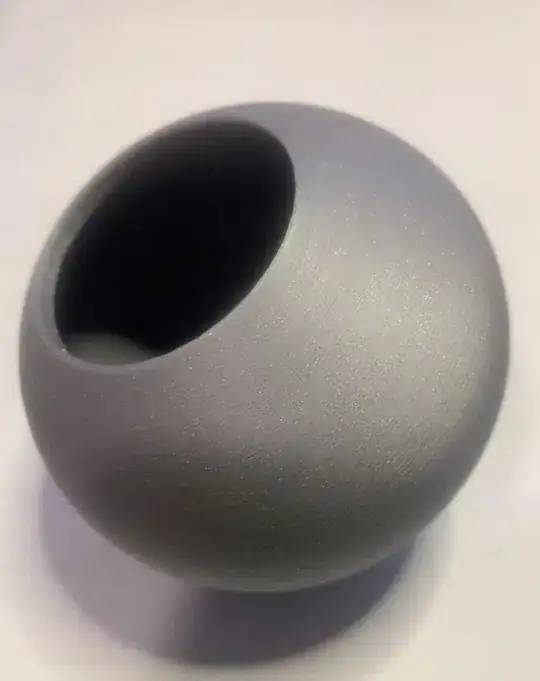

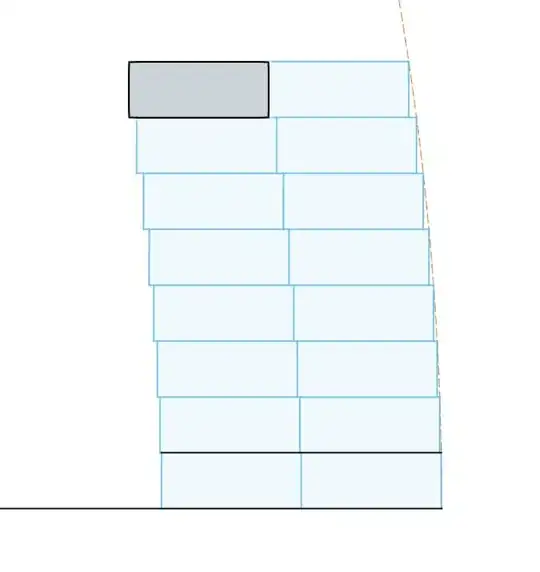

I have a model of an eye that I custom made in Blender 2.83 that when printed only creates roughness on the printed object near where I had the supports. The supports are not the cause of the roughness (at least not completely) since the supports don't even touch the parts of the print where the majority of the roughness and bumps are (refer to my photos of the print)

The roughness is only near the bottom part of the sphere as it prints upwards (refer to photos)

What I'm looking for is a technique or any suggestions for printing this without the roughness so it's smooth like in the rest of the print. I'm also curious what is causing the roughness.

Eye Model in Blender

Blender Scale Ratio: 0.001

Blender Units: mm

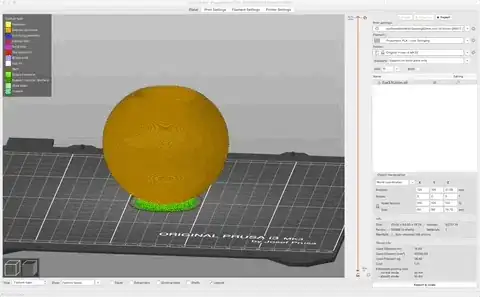

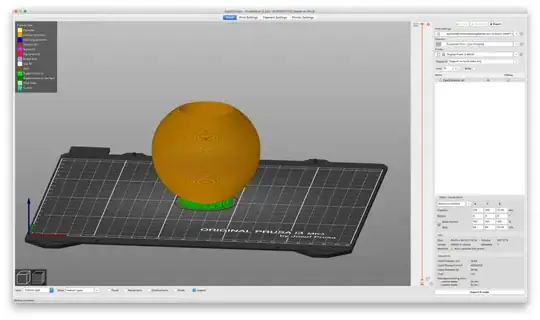

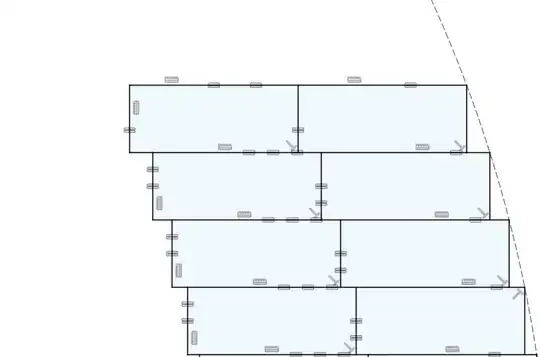

Eye Model in Prusa Slicer

Layer Gif

Prusa Slicer Main Settings (Higher Res)

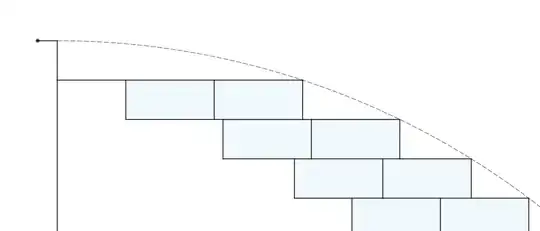

Variable Layer Heights For Smoothness

Eye Model Prints Photos

Eye Model Small Version 3D Print (Notice it's smooth on top of print)

Eye Model Small Version 3D Print Trouble Area

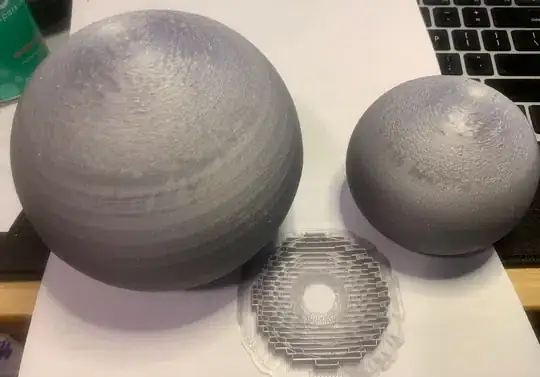

Eye Model Small & Large Version With Support (Notice roughness on the sphere)

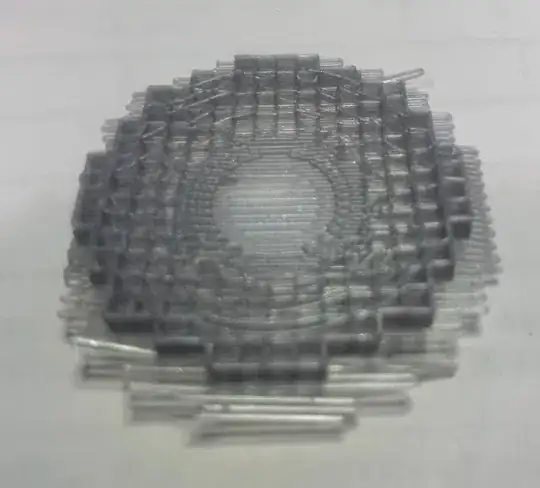

Example of Support Used On Small Print

Smooth on inside of print

--------- Print Details ---------

Printer: Prusa i3 MK3s

Filament: PLA Galaxy Silver (Prusa Reserach)

Slicer Software: Prusa Slicer

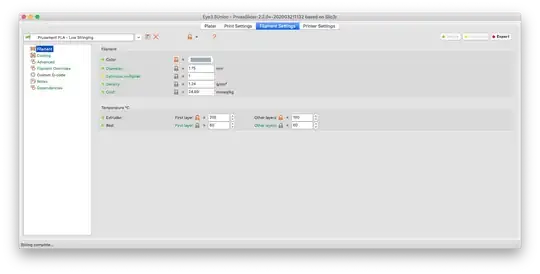

Print Temperature First Layer: 205 degrees

Print Temperature Other Layers: 190 degrees

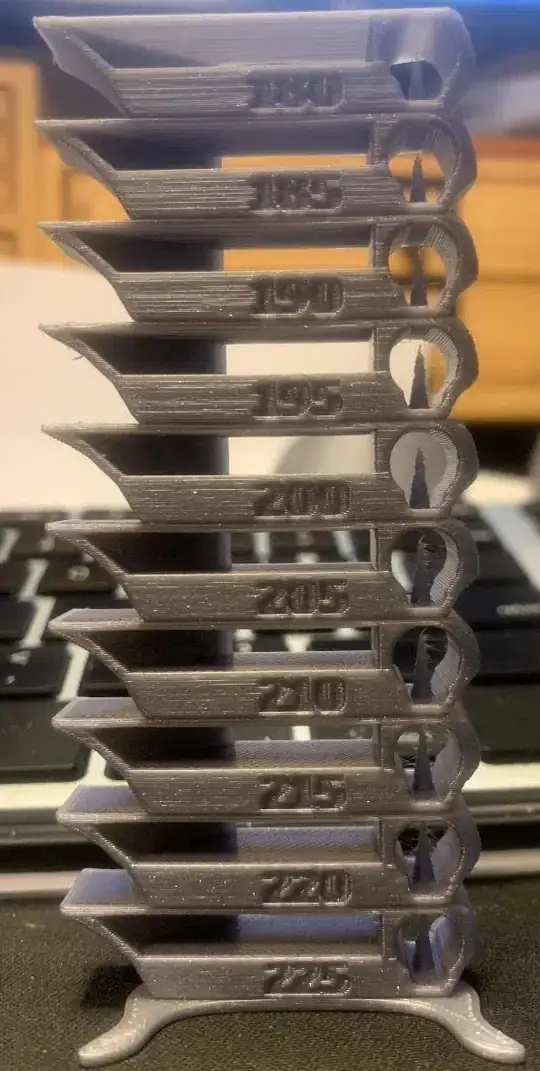

Notes: The suggested temperature for the filament is 205-215, I've adjusted after careful calibration given my environment to a lower temperature to reduce stringing. I created a tower at different temperatures and discovered 190 was the perfect setting to reduce stringing in my case with this material. Refer to my screenshot below. I do not think temperature has anything to do with this since the print is smooth inside and near the top without any issues.

Temperature Tower Test For Filament Photo:

(Note stringing in the cone test areas at 225 to 205)

--------- Prusa Slicer Settings Photos ---------

Filament settings

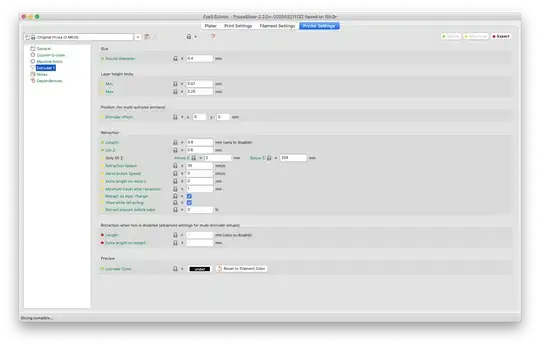

Extruder Settings

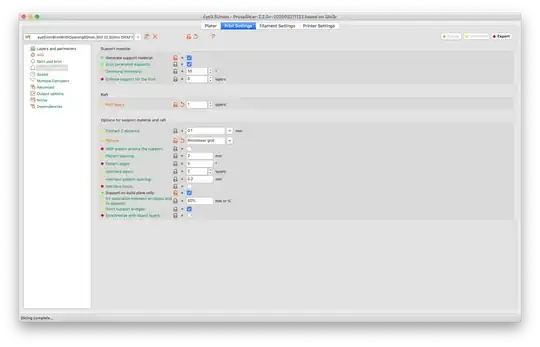

Support Settings