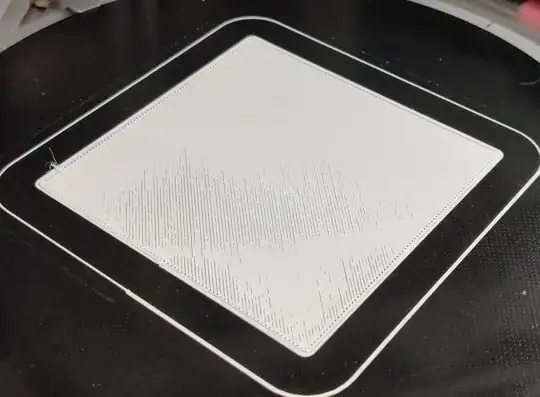

When I print the gcode repeatly, under extrusion happens at the same place.

The under extrusion not only occurs on first layer. I noticed the second layer also has some part under extruded, but not at the same place as first layer, because the infill line direction is rotated 90 degrees.

I have tried the following but could not solve the problem:

- Delta calibration (leveling)

- z=0 gap adjustment

- Filament flow calibration

It's a delta printer running Marlin 2.1. Slice with SuperSlicer.

The top layer doesn't seem to have under extrusion. There is even a bit over extrusion at the corner.