I upgraded my Ender 3 V2 with a BIQU H2 hot end and extruder head and a BLTouch probe. I updated the firmware from Ender website using Ender-3 V2_32bit_4.2.2_BLTouch_Marlin-2.0.1 - V1.1.1.bin. All hardware seems to work flawlessly, incl. all axis movements, extruder movements, heating, fans controlling,...

However, I don't know how to really proceed with changes to extruder settings. I found no YouTube videos or internet articles, particularly about "Ender 3 V2" and "BIQU H2" and what I found is not compatible.

From what I gathered, I need to change the speed ratio of extrusion and the gear ratio of extrusion. But I don't know how to set it on Ender 3 V2. I tried to configure the gear ratio. There's a nice YT manual for Ender 3 V2, however for the old extruder, so I couldn't measure the extruded filament beyond the extruder. I made a line 100 mm above the extruder with a marker and set the extrusion to +100. I got something like 10 mm of snail-pace slow extrusion. So I went to the extruder's gear ratio and tried to raise it, but the value should be roughly $100 / 10 * 93 = 930$ (93 was the default and current value). However, the adjustment goes only to 186, and with that, I get a little bit less than 20 mm of extrusion. And I also suspect that the extruder's speed is about 7 times smaller (1:7 gear ratio) than what it is supposed to be.

So, could you advise or direct me to materials that explain how to set BIQU H2 on Ender 3 V2? Is there anything else I have to set, apart from extruder speed and gear ratio? Some tutorials mentioned about stepper motor voltage if I remember correctly, but again, that cannot be set in the menu. I'm fine with settings over G-code, as long as I have some clear instructions on what actually to set.

Note:

I marked Oscar's post as an answer, though to me it tells only part of the story. But helped to clarify some stuff. Be careful and study the matter yourself, however, you should come to this conclusion and those steps for Ender 3 V2 and BIQU H2, particularly for setting the extruder motor current.

Disclaimer: Those were my steps and I do not take any responsibility for anything if you follow them. Check everything yourself and advice in the comments below, if anything doesn't look right.

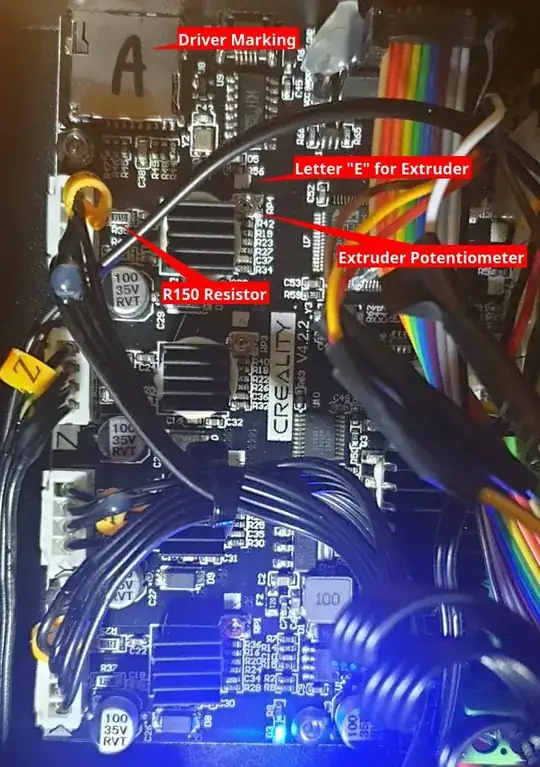

Check you have TMC2208 - you should have the large letter A written on your card reader

Check your BIQU H2 stepper motor nominal voltage is 800 mA in the attached manual

Check the resistors at the stepper motor (marked E) on your main board are R150 (150 mΩ)

If all above is true, you should get Vref = 1.05. Based on

$\frac{0.8}{\sqrt{2}} = {\frac{325mV}{150mΩ+20mΩ}*\frac{1}{\sqrt{2}}*\frac{V_{ref}}{2.5V}}$

I separated voltage:

$V_{ref} = \frac{0.8A/\sqrt{2}}{325mV/((150mΩ+20mΩ)*\sqrt{2}*2.5)} = \frac{(150mΩ+20mΩ) * 2.5 * 0.8A}{325mV} = 1.046V$

Measure your current Vref with positive contact on the potentiometer and negative on the card reader cover, using an appropriate scale on your Voltmeter, i.e. up to 20V DC. You should get something like 1.4 V, if you have the default factory setting. One hint: I put a piece of insulation tape on the cooler next to the potentiometer in order to avoid a short circuit in case the cooler is connected to the negative body - it's easy to touch it with a screwdriver. Remove it after the correct voltage is set. Or use a plastic or ceramic screwdriver.

Turn slightly the potentiometer anti-clockwise, about 1/5 of the circle for start, and measure the voltage again, then do a fine adjustment, measure again, etc., until you get desired value. I could set it from 0.03 to 1.02, meaning that I set 780 mA, slightly below the nominal voltage.