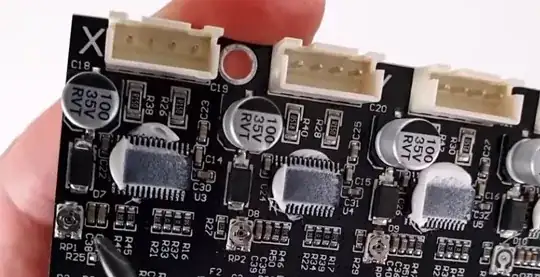

I upgraded my Ender 3 with a new Mobo, the 4.2.7 version.

My current setup is:

Printer Specifications:

- Ender 3

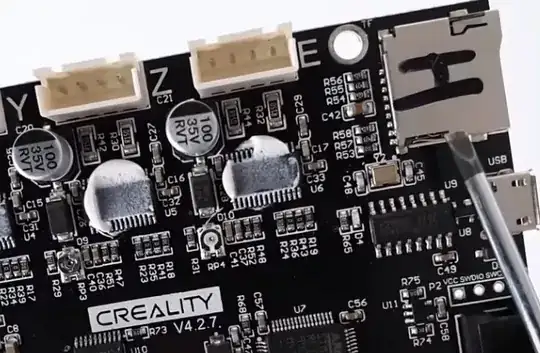

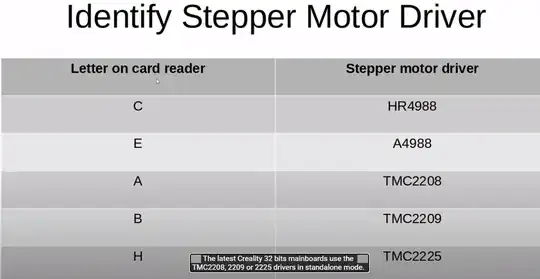

- Upgraded Motherboard 4.2.7 (Silent Stepper Drivers)

- Marlin FW Upgrade to Version 2.1.x

- New metal extruder handle

- Replacement bed springs

- New complete hot end

- Everything else is in stock

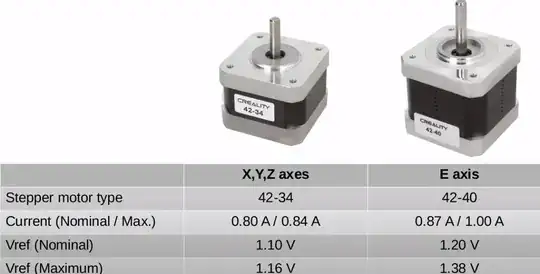

Prior to the mobo upgrade, everything was working fine. Now I'm having problems with the extruder. I did use at first the Ender3 32bit 4.2.7 firmware, but it did happens too. The e-steps for the filament length have been adjusted. Once I start spinning the extruder, the extruder stepper starts grinding and jumping/rewinding the extruder wheel with the filament to the back; sometimes even 8-10 mm. Also, if I manually hold the filament back, it springs back. It seems that there is no power/power coming from the stepper motor.

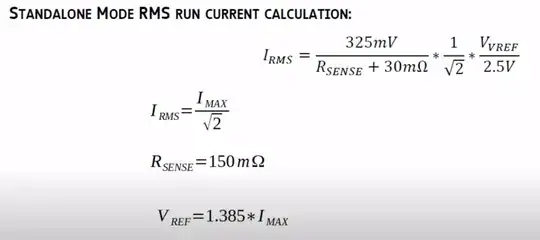

So I would like to check how much power the driver needs and gets. How or where can I find the required voltage for the drivers? How to adjust the drivers?

Any tips or references are welcome.