Many ways lead to Rome!

There are many ways that lead to Rome in this case, and I want to propose two:

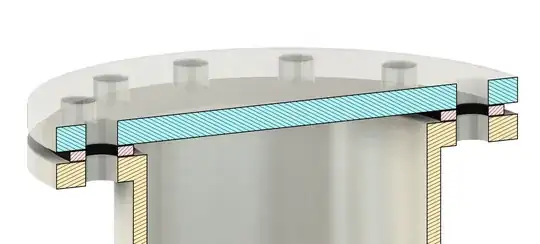

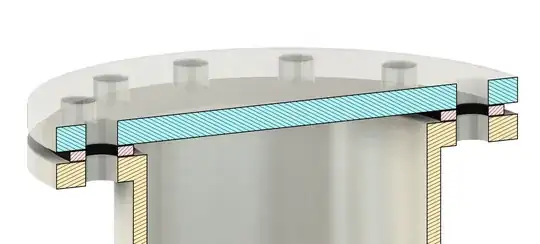

cut gasket sheet

The most simple solution is a gasket, upon which pressure is applied evenly on all sides. This gasket can be made from any rubbery or foam material and then squished between the halves. A typical construction for a gasket would look akin to this stack: a pipe with holes in the flange at its end, then the gasket, then the endcap. The sealant is deformed against the plates on either side and the pressure is applied by having bolts pass through the faces and the gasket. You'll find this mechanism often where flat surfaces are mating. The thickness of the gasket and its flexibility (some are really stiff, others are super soft) are dependent on the use case. They rely on being tensioned evenly.

Among the household solutions that can work like this are 2mm closed-pore foam sheets and faux leather. The latter usually is a PVC foam, at times fiber reinforced. Industrial gaskets are at times papery in make but rely on precision machined surfaces then (motorhead gaskets!)

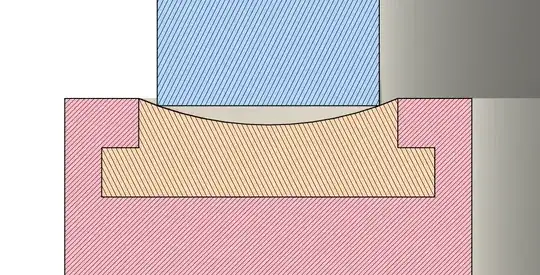

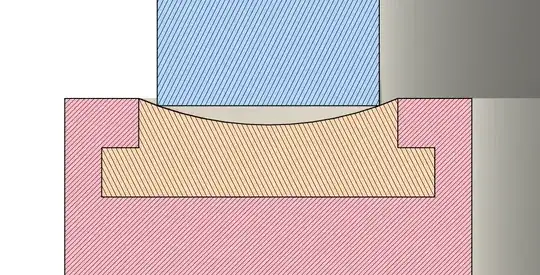

molded gasket by the sealant grove in situ

In this case, you use a flexible rubber material, such as acyl, silicone, or a Polyurethane sealant, and add it to a groove or onto a surface. In this position, it cures into a staying gasket and when brought in contact with the mating surface, it provides sealing surfaces by deforming in the fashion limited by the channel provided for it. The upside is, that you can have very complex mating surfaces. The downside is, that often the seal might not be replaceable easily and will need to be destroyed to get a replacement done.

In the example shown below, I designed the receptacle for the sealant in the shape of a grove, allowing you to easily shape it with a coin or wet finger and press it into all crevices of the channel. This will result in a well-curing and maximum-adhering shape.

A slight refinement on the design would be an undercut on the receiving side, preventing one from pulling the gasket from the channel if the inside of the vessel had a lower pressure than the outside and the mating surface sticks to the seal. However, this makes replacing the sealant harder if it ages over time.