First time trying the EasyPrint Flex TPU filament. When printing a solid, I can see clear lines with plenty of air on both sides. This gives me the idea that it is not extruding enough filament.

I've tried many tweaks:

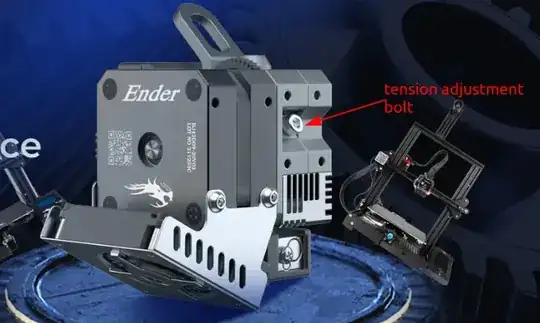

- Adding/removing tension to the extruder

- Pulling at the filament to see if the gears have a good grip at it (they do).

- Printing at ridiculously slow speeds (5 mm/s)

- Bypassing the runout sensor, in case that is adding too much friction or something.

- Adding flow rate in Klipper (maxes out at 200 %, slight improvement)

- Adding flow rate in Cura to 600 %

The last tweak makes the most apparent improvement. Printing at 25 mm/s, it's somewhat decent. There's still some air going through each layer, but much less. The result is still dissatisfactory.

As this printer uses a direct extruder there shouldn't be any problem with the feeding.

Can I now conclude that this is simply a crappy filament and my best bet is to buy something better? If not, then am I missing something obvious here?