I have been printing on and off for years. Generally, I have had no issues until recently. Upon thinking back I don't think I used the Z-offset at any point and only manually leveled my Ender 3 S1 Pro.

I'm not sure if it's material or me, or both.

I have to learn this. I bought a new, expensive printer which is ABL only. No knobs, only Z baby-stepping in software. The card reader in my S1 broke so I bought a new board and discovered I needed to do this process again. Since I purchased a Sonic Pad, I changed over to Klipper and printed TPU for 2 weeks fine.

I bought a spool of Overture PLA, it's been a disaster. Before trying to dial this in last night the spool had been drying at 45 °C for 12 hours. Doesn't seem to print any differently.

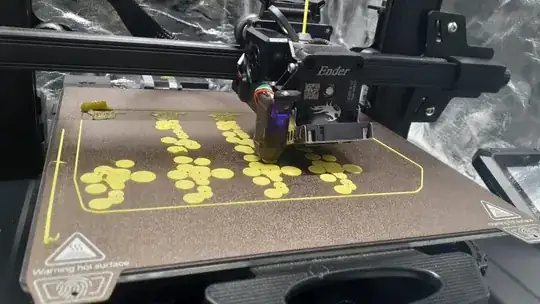

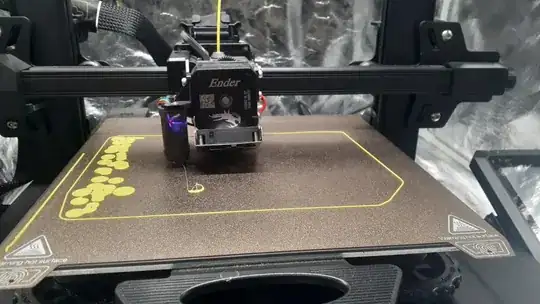

Instead of the config steps, after manually leveling and getting the mesh, I made a one-layer print of concentric squares with a solid 1" box in the center. I'm baby stepping trying to find the sweet spot and think I do. I begin printing my model, 5 copies, layer 1: 1 - doesn't stick; 2 - sticks; 3 - sticks; 4 - sticks. I stop and clean the bed with IPA. Copy 1 - sticks; 2 + 3 - doesn't stick. Stop printing, manually level, and find no resistance with paper. Re-level manually only, print, skirt doesn't lay down right.

Tried the Creality "BuildTak" bed first, and worse.

- Printer: Creality Ender 3 S1 Pro - Sonic Pad (Klipper)

- Nozzle: 0.5 mm Hardened Steel @ 215 °C

- Bed: 60 °C PEI and "BuildTak"

- Layer Height/Width: 0.3 mm 0.5 mm

- Filament: Overture PLA Highlight Yellow

- Speed: 25 mm/s

What's the process? 1) Manual 2) Probe 3) Mesh? Does the order of 2 and 3 matter?

Mesh and manual are easy enough. I won't be at my printer until 7 pm Central be eager to read any advice during the day. I have Googled this also; obviously, I missed something.