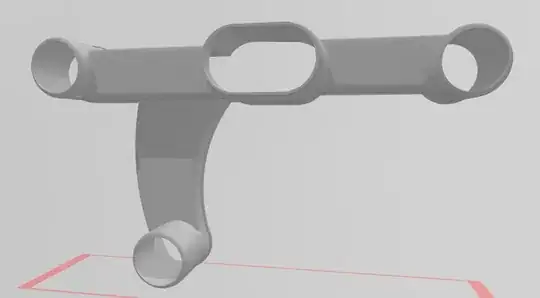

This shape wasn't designed for 3D printing

Some of your requirements are contradictory in 3D printing context.

- Smoothness inside indicates that you need SLA or DLP process.

- 2mm walls will be too brittle using SLA/DLP.

- Being able to be removed and reinstalled couple of times per week pretty much requires FDM with great layer adhesion.

- Sharp 90° angles we see on the picture exclude FDM print if you want it to be sturdy.

If you want to print it, you need to redesign it in a way that will remove issues above - make walls thicker, chamfer or round all the 90° angles, and forgo the smoothness requirement on the inside, or figure a way to line it with something like automotive filling primer.

ABS Injection is the only way to replicate it exactly and keep its functional parameters.

Alternatively, print a mold, and remake the item using carbon or glass fiber pre-pregs. It will be light (carbon variant), extraordinarily sturdy and stiff, and you can use gelcoat or polishing to get it smoother than prints will ever be. You will still need to decide where shape of the internal surface is important, and where the outside takes precedence, and I still strongly recommend to round out all 90° angles, but rounding radius can be smaller, as long as you are comfortable with forcing pre-preg to follow it. It'll just make your life easier to have them larger.

There is a lot of tutorials on the Internet on how to do it, but I believe specific issue with this method belong to a follow-up question, not here.

I have a large part, a chute that measures 638.54 × 152 × 369.05 mm, with a 2 or 3 mm wall thickness. This part was originally was ABS that was injection molded. Smoothness is required on the inside of the chute and rigidity is important as it could be removed several times per week. I can have it printed in Nylon PA12 with either MJF or SLS or in ABS with the FDM process with 100 % infill.

I have a large part, a chute that measures 638.54 × 152 × 369.05 mm, with a 2 or 3 mm wall thickness. This part was originally was ABS that was injection molded. Smoothness is required on the inside of the chute and rigidity is important as it could be removed several times per week. I can have it printed in Nylon PA12 with either MJF or SLS or in ABS with the FDM process with 100 % infill.