I printed a Raspberry Pi camera arm for my Ender 3 V2 as a second camera that's not connected statically to the printer frame but to the printer bed instead. I now have two cameras, both from different angles, each with advantages.

However, the moving bed results in severe vibration. I need anti-vibration or stabilization methods for my very light Raspberry Pi camera. I was thinking about doing something with some rubber bands somehow or making a mold to make a silicon block(s) that I will use to replace some part(s) in the middle of the arm, disconnecting the plastic so it can potentially absorb some vibration.

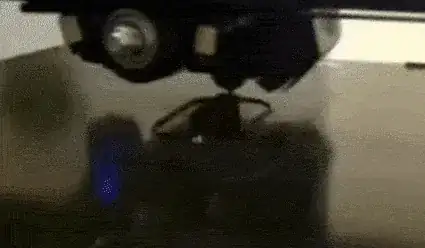

Below is an example of the vibration viewed from my Raspberry Pi camera. The image is cropped, speed up and compressed to fit in an animated GIF under 2 MB for this site. The original is in higher resolution but the vibration is visible.