It is my first time printing flexible filaments.

I have been trying to print a flexible case for my mini-PC using the TPE 83A by eSun on my KP3S pro.

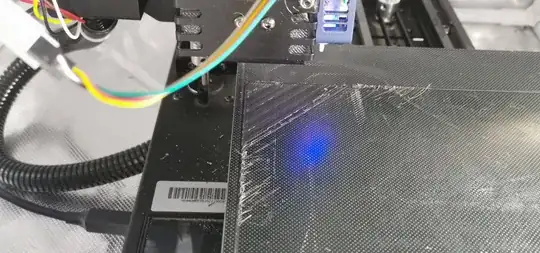

Whenever I try to print it starts well, then after printing a few strokes, the print systematically fails. It is not an adhesion/levelling problem as I installed a BLTouch probe and made a 12x12 points grid of my 200x200 printing bed, which works perfectly with PLA. It seems that after printing a few lines, the nozzle just stopped extruding filament anymore (see photos); although the extrusion gear still seems to be turning.

FYI my nozzle is a hardened steel nozzle, that I recently acquired to replace the original brass nozzle (because I wanted to print abrasive filament). Could it be the problem? I read that a hardened steel nozzle may not conduct heat as well. I did try a wide range of temperatures and saw the same results; also given the small size of the MK8 nozzle used by the KP3S, I would wager that heat losses due to poor heat conductivity of the nozzle may not be as important no? (I guess that the delta in temperature between the contact point with the heating also depends on the length of the nozzle)

Other information:

- I print in an enclosure

- I try to keep my filament dry by using a heating box + desiccant

- Also the filament doesn't seem to warp, the filament that is on the bed seems to be well adhered. The problem seems to come from the "extrusion system", whereby the filament just stops extruding.

- I used the recommended printing profile for flexible filament (e.g. reducing speed to 35 mm/s for top speed and to 20 mm/s for the first layers, retraction distance at 1 mm)

Any idea of what might be happening? I gleaned a lot of info from Proper settings for printing rubber and rubber-like materials? on printing flexible filaments. I will perform a bunch of tweaks based on that question to hopefully troubleshoot my way to a proper print through trial and error; however, it would be nice if someone has a better idea that could direct me as to what could be the problem given the symptoms observed.