It depends on your printer really. If you have a direct drive printer with all metal hotend, then you can feed filament directly into the carriage without any guiding tubes.

For example, the Prusa i3 models (MK3, MK3.9, MK4) don't require any tubes, as shown in Prusa's own promotional photos:

Edit: It seems this is misleading marketing, as there is apparently ~5cm of PTFE internal to the carriage.

As for replacing a Bowden tube with something other than PTFE... I don't know any of concrete examples of a proven solution, but really any tube in which you can easily slide your filaments (i.e. low friction) will do.

If you are printing PLA and PETG I would expect you can get away with using Polyurethane ("TPU"), but might need to lower your speeds to overcome the friction. I've not tried any, but I can see that if you are in the US (I'm not) you can get a variety of soft (i.e. flexible) tubing from McMaster-Carr

The inner diameter may differ slightly from the usual PTFE tubes the printers come with, in which case you may need to tune retractions (larger inner diameter -> more retraction needed).

If you have an all metal hotend, then the Bowden tube itself won't be subject to high temperatures, so the important characteristics will be its inner diameter, whether it can flex the way you need for your particular printer, and if filament can be pushed through it with relatively little resistance.

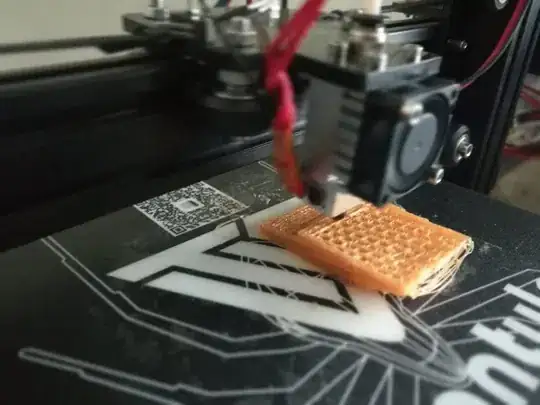

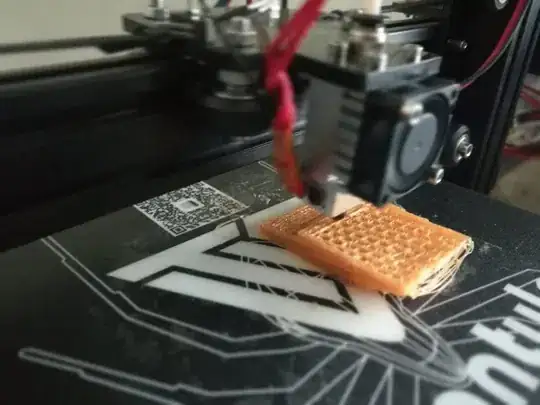

If you are feeling adventurous, you could even try printing your own tube from TPU and see if the idea can work at all. I'd use some of the stiffer filament, perhaps with a shore hardness of 98A which when printed solid is about as tough as shopping trolly wheels. If you print it thin it bends quite easily.