Cause and effect

Bent screws can cause an effect known as Z-wobble. But, to mitigate this, the non-driven side of the lead screw is left unconstrained. This is intentionally designed as such.

This means that as long as the linear guide (being V-slot with rollers, linear shafts or linear rails) are sufficiently guiding the carriage, a little bent screw would not cause too much problems in the print result.

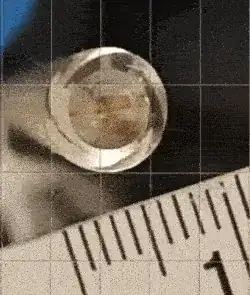

Note that the animated gif shows the end displacement, this exaggerates the actual displacement experienced by the lead screw nut.

When is a leadscrew too bent and should be replaced?

If it causes quality issues in your prints.

E.g.:

Mitigation

Buying new, straight leadscrews. Usually, the more straight the more expensive, the lead screws from the far East range from acceptable to unusable. Ball screws are much more precise, but also cost more, especially the ground screws.

Some people straighten the lead screws, there are videos to be found how you do that.

But, note that there is an option not to replace the screws!

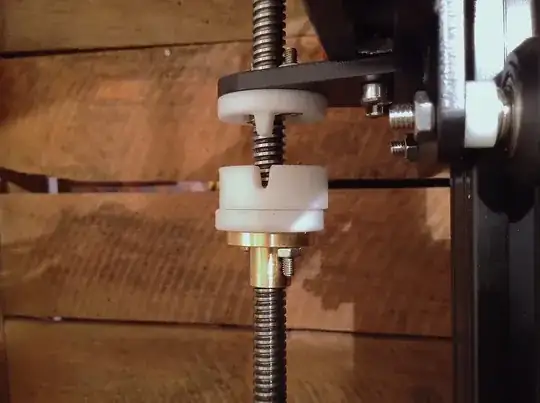

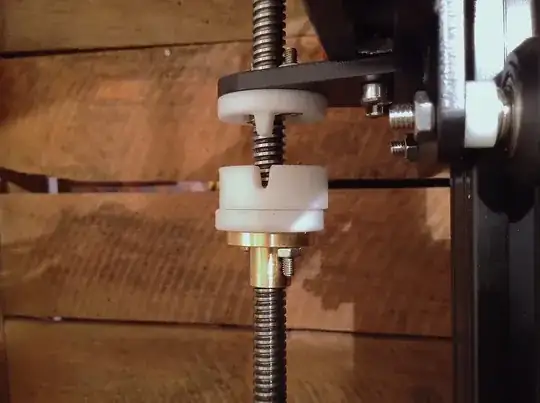

E.g., to completely remove any wobble of the lead screw, you can use something called an Oldham coupler to decouple the X-Y movement from the Z movement. For Creality Ender printers, there are specific couplers to order to install so that you will not need to buy new lead screws.

Custom printer designed Oldham couplers look similar to:

There are also printable versions that work very well, in fact I designed and used my own, inspired by this design: