It depends on the size of the nozzle you are using. If you are using a small nozzle, e.g. 0.2 mm, normally, you should increase the nozzle diameter (filament manufacturers often refer to about 0.5 mm nozzle diameters). Wood/cork, or whatever particle filled filament requires a somewhat larger diameter to prevent clogging.

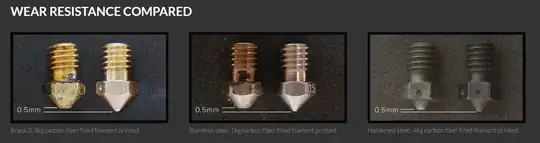

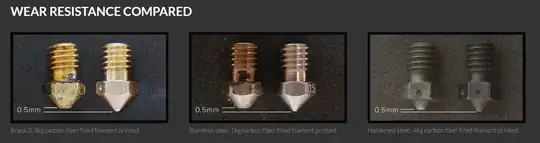

In addition to Tom's answer, note that there are stainless steel nozzles and hardened steel nozzles. The latter is harder than the prior and should be used for abrasive filaments, like filament filled with metal particles or some sort of abrasive fibres like glass or carbon fibre. Note that the addition of fibres or particles may require you to increase the nozzle diameter as fibres or particles may cause clogging. A last nozzle discussed is the nozzle with an embedded industrial Ruby, a design of Anders Olsson, a research engineer at Uppsala University, more information is found on the Olsson Ruby website.

From the Olsson Ruby website, the following interesting image is shown, comparing the wear resistance of the various nozzle materials up to 0.5 mm (from left to right; brass, stainless steel and hardened steel by printing respectively 0.3 kg, 1.0 kg and 4 kg of carbon fibre filled filament):