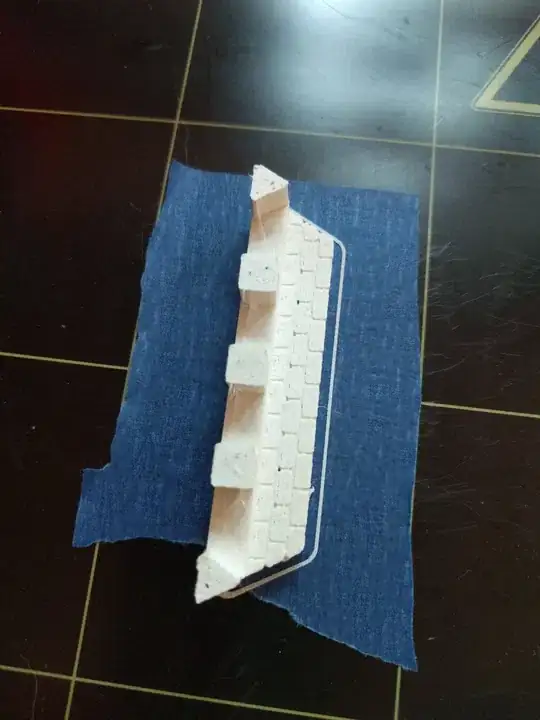

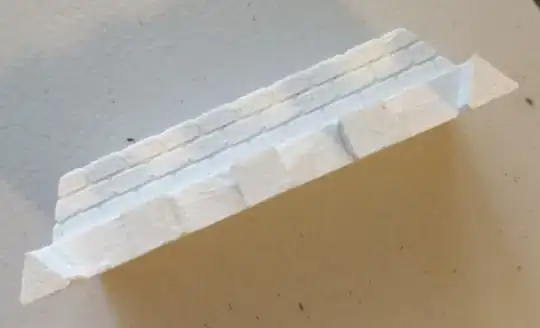

I'm trying to print with Laybrick and for the most part it is going. The problem lies with the top layer and gaps appearing. I've tried increasing the number of top layers but the gaps still appear. Any ideas what else I can try?

-

Did you try raising the temperature? I would have done that second after increasing number of top layers. – fukanchik Oct 04 '16 at 17:25

-

Raising the temperature leads to a different texture which I don't want. – easycheese Oct 04 '16 at 17:44

2 Answers

When using Simplify3D, you may try referring to their awesome troubleshooting guide: https://www.simplify3d.com/support/print-quality-troubleshooting/#holes-and-gaps-in-the-top-layers 3 reasons (from the guide) for gaps in the top layers:

under-extrusion: you may try to increase extrusion multiplier to see if this helps

low infill percentage: not likely in your case if increasing number of top layers did not help

not enough top layers: you already tried increasing number of top layers.

In addition to that, you may change certain parameters (such as extrusion multiplier) for a given number of layers by using Simplify3D features. It can be helpful to avoid problems to for the rest of the model.

- 878

- 6

- 13

-

-

It did help (I'm already aware of that site) but cost to much to implement for the pieces – easycheese Oct 04 '16 at 22:28

-

You can create more than one "process" for a certain model and assign them for different ranges of layers. – Mikhail Z Oct 05 '16 at 08:13

-

I don't believe you can assign different layers, just z height. Plus I have heard there are a lot of issues doing that – easycheese Oct 05 '16 at 11:58

-

This may perhaps depend on the version, but what I've seen is a layer range in 'Advanced' tab. Going back to your original question, I would rather start with increasing flow rate (or checking actual nozzle diameter). – Mikhail Z Oct 05 '16 at 12:22

The solution was a combination of several items. The primary one was slowing down the top layer of the print significantly. I was using 3200 mm/min for the print and used the option 'solid fill underspeed' to slow down the top layers to 40%. I increased the top layers to 7. I also increased the infill, to ensure there was support in the tiny top pieces. I also decreased the minimum infill length to 0 to ensure the infill went in tiny places. Finally, I used the 'Concentric' external fill pattern.

At some rotations of the model, I had slight gaps in the corners of the model, increasing the number of outline layers fixed it.

I also decreased the temp to 160 compared to the initial print above.

- 417

- 1

- 3

- 13