I have two theories to offer.

It is really dripping. If this is the case, the likely culprit is a loose part in the hot-end, namely the nozzle/heating block coupling, or the heating block/heat break one. If this is the case, you should be able to see it by visually inspecting the part. The solution in this case is to fully disassemble the parts, clean them thoroughly of any remaining plastic, and reassembling them while hot. This is essential, as parts that are assembled cold have the tendency to come loose when heated (due to thermal expansion).

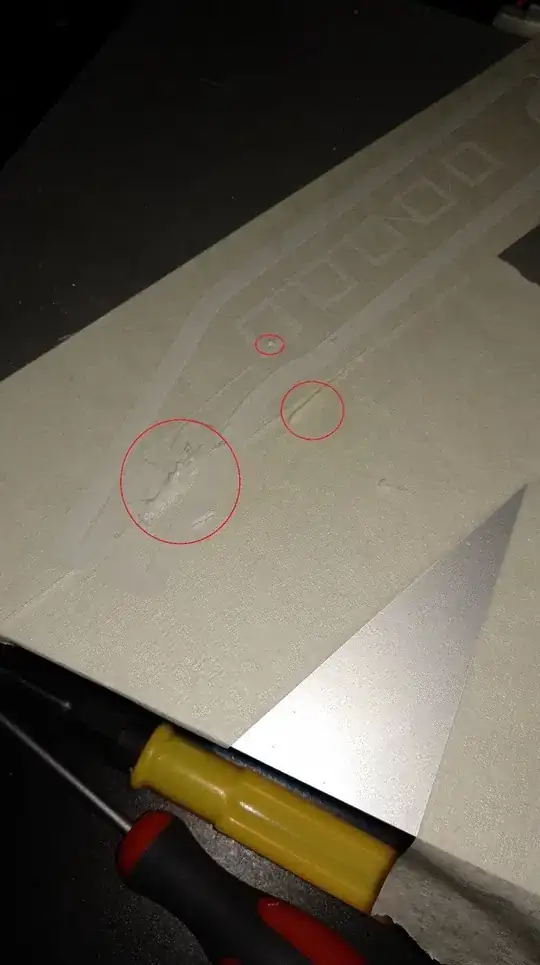

It is overextruding, and the nozzle collect and drag around the excessive plastic, until the blob is big enogh to detach and remain on the bed. If this is the case, then you should calibrate your extruder, and the nozzle height.