I am a complete newbie at 3D printing (although learning fast). I switched from the default Qidi slicer to the Cura slicer on a Qidi X-Pro machine (which is wonderful). Using: plate 50 °C, 0.4 mm nozzle 200 °C, 1.75 mm PLA, print speed 20 mm/s outer wall, 40 mm/s inner wall, travel speed 100 mm/s (the cura default, I think).

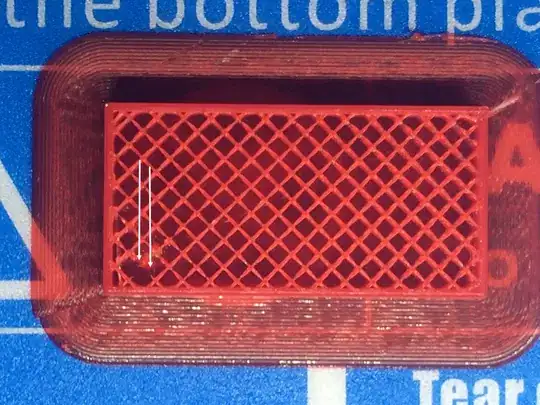

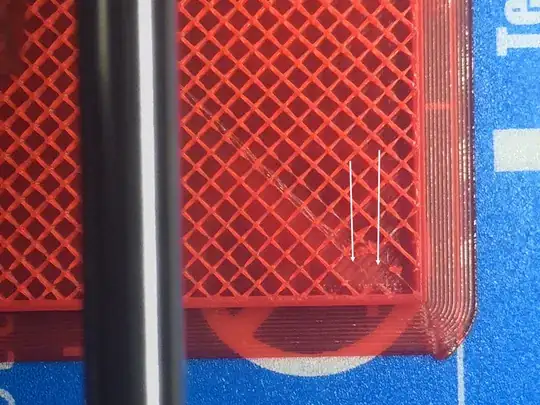

On two different prints, the same far corner (front left) had initial infill problems. Does anyone know why, or how I can solve it? My working theory is that the nozzle shoots across the whole print at high speed to start again at that corner and sometimes the infill filament doesn't bite enough to stick.

Eventually one of the infill layers gets a bite and the rest of the print is fine. But it's disturbing that it occurs on different prints. (I carefully level the plate before every print, so I don't think that's the issue.)

UPDATE

In another question here, turning the Cura combing setting off solved an issue. It probably solved the issue described here, too, or at least contributed to solving the problem described here.

My theory is that with combing on (as it was for that question), the oozing pulls filament out of the nozzle during the travel, so there's not enough filament at the destination corner to bite and bond to the corner wall. Turning the combing setting off seems to have solved the missing infills in the corner. It also greatly improved the quality of the infill walls, too, which relates to the problem described in this question.

UPDATE: Here's a paragraph from a forum posting here that explains how oozing caused by combing can result in "underextrusion effects." That's what I think is happening in this post - the nozzle gets to the corner, but it has no filament to bite and bond with the wall. Credit to @0scar for giving me the forum link. Quote from the link:

Even on interior layers, combing as implemented in Cura is a bad idea, as it doesn't perform retraction, and that can result in the head oozing as it moves, especially as each time the head crosses a line of infill it can tend to pull our some plastic. You can also get some long moves (e.g., all the way around the curve of a 'C' shaped object when moving from one side of the opening to the other). This can result in the head being empty when it starts printing the perimeter again, with resultant under-extrusion effects.