I have had a Creality Ender 3 v2 with a 4.2.2 motherboard for about 2 years. It's a company-owned machine but I got it just about when Covid hit so it has only been used at home. It worked OK at first. I used it a good bit. Then I got a Prusa and liked it better so I mostly used it for both work and personal stuff.

Now Covid work-from-home is over and I have moved my Ender 3 back to my office. I also installed a BLTouch I bought a long time ago but never got around to installing it. I had a devil of a time getting the BLTouch to work. It would quit halfway through leveling. I ended up installing Jyers firmware with a 3x3 leveling grid and now it prints. Kewl!

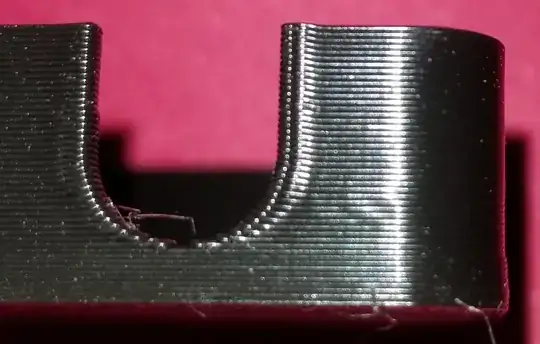

Now I have an issue where none of the dimensions on my prints are correct. I am printing a housing for a circuit board so the dimensions have to be correct or the circuit board will not fit. X, Y, and Z are all undersized. Worse yet, the first 3 or 4 mm in the Z-axis layers are squished. It's like elephant's foot on steroids. I attached a photo.

So the X and Y dimensions of the print are oversized at the bottom due to the elephant's foot but are undersized at the top. The Z-axis dimension is way undersized because of the squish.

The Jyers firmware has a "steps/mm" setting. I haven't changed it from default. Creality's specs say the printer is capable of 0.1 mm resolution but it doesn't say steps/mm so I have no idea whether default settings are correct in Jyers firmware. Jyers was developed specifically for the Ender 3 v2 so I would expect it to be right.

I checked all the rollers on all axes and they look fine. I checked the coupler on the Z-axis stepper and it is tight. I can't find anything loose. The rails are clean and no foreign matter is present. The belts are tight.

I am printing with Hatchbox PLA. I have always had success with this stuff on my Prusa.

I compared the default PLA temps for Creality vs. Prusa. The Prusa runs the extruder at 220 °C vs the Creality running at 215 °C. I am using PrusaSlicer for the Creality.

A related issue I am having is the supports. When I print with supports on the Prusa the supports break off easily. I can usually break them off with just my fingers. The same supports on the Ender 3 v2 require pliers. The support material is binding to the model too tightly. The elephant's foot would explain why supports on the lower layers would be wonky but even supports at higher layers are hard to remove.

I replaced the nozzle with a new 0.4 mm unit hoping this might help. No improvement.

Any ideas?